Electric Car Shipping: How to Minimize Risk

- Vegard Synnes

- Mar 7, 2023

- 6 min read

Updated: Apr 28, 2023

We have on several occasions written about how the Kar-Tainer Cassette Systems can be utilized for safe loading and transport of electric vehicles in containers. Due to the huge interest shown towards shipping electric cars in containers, we wanted to revisit the topic and discuss some of the general safety concerns in the industry in regard to transporting electric vehicles, highlight the differences in shipping EVs in containers compared to conventional RoRo transports, and discuss some of the safety features which can be applied to containerized transports to minimize the risk of fire or other accidents.

The Hazards of Electric Vehicle Transportation

Shipping electric vehicles (EVs) poses certain hazards, primarily related to the cars' battery systems, which store large amounts of energy. Here are some potential hazards associated with shipping EVs:

Fire: EV batteries can be damaged during shipping, which may result in a fire. EV batteries contain flammable electrolyte fluids, and if they ignite, they can be difficult to extinguish.

Damage to the battery: The battery pack in an EV is heavy and can be easily damaged if the vehicle is not handled properly during shipping. A damaged battery can potentially cause a short circuit or leak, leading to a hazardous situation.

Overheating: During shipping, EVs can experience extreme temperature changes. If the battery overheats, it can cause thermal runaway, which is a chain reaction of increasing heat that can damage the battery and create a hazardous situation.

Electrochemical reactions: The battery chemistry in EVs can lead to electrochemical reactions if the battery is damaged or if the vehicle is exposed to water. These reactions can produce hazardous gases, such as hydrogen and oxygen, which can be explosive.

Transportation regulations: There are specific regulations that apply to the transportation of EVs due to their hazardous nature. Shipping companies must comply with these regulations to ensure the safe transportation of EVs.

Overall, shipping EVs requires proper handling, packaging, and transportation to mitigate the risks associated with their battery systems. And for these reasons we can see how shipping companies and logistics providers refuse to handle second hand electric cars, set regulations on the level of charge an EV can have during transport, adding dangerous goods surcharges to shipments of EVs, or establish special processes on how to handle electric cars in a safe manner.

If misfortune strikes and a fire erupts during transport of electric vehicles there are different methods to extinguish a lithium battery fire depending on the size and type of battery involved:

Lithium-metal battery fires can be put out using Class D fire extinguishers. On the other hand, lithium-ion battery fires are classified as Class B fires due to the presence of flammable liquids. To extinguish this type of fire, a standard dry chemical or ABC extinguisher can be used.

Extinguishers designed specifically for lithium battery fires work by neutralizing the liquid electrolytes that create conductive pathways.

Small lithium batteries contain a small amount of lithium and can be extinguished using water. For larger lithium-ion battery fires, a foam extinguisher containing CO2, powder graphite, ABC dry chemical, or sodium carbonate should be used.

In battery pack fires, each cell may ignite at a different time, making it difficult to control the fire. It is recommended to place the battery pack in an outdoor area that is protected and allow it to burn out completely.

If the fire cannot be extinguished, it is advised to let the battery burn out in a controlled manner. To prevent the fire from spreading, the surrounding area should be soaked with water.

Firefighting at Sea

Besides the regulated equipment and processes for fire detection, prevention and suspension, lined out in SOLAS (Safety of Life at Sea) chapter II-2 there are different methods of suppressing a fire onboard a RoRo vessel. Specialized fire blankets can be used to cover the vehicle on fire to stop the fire from spreading from one vehicle to another, decks can be closed off to attempt to limit the fire to only a certain part of the vessel, or a water drenching system can be used to completely drench out the fire, this does however present its own difficulties as it may lead to bigger problems as the vessel may experience a loss of stability.

If there is a fire in a container onboard a container vessel on the other hand, it's still essential to isolate the container catching fire from other containers and the rest of the ship to prevent the fire from spreading. Here are some steps that can be taken to isolate a container fire onboard a container ship:

Use the ship's fire suppression system to contain the fire by flooding the affected container with fire extinguishing agents such as CO2 or foam.

Close all ventilation and air conditioning ducts leading to the affected container to prevent the spread of smoke and fire.

Use thermal imaging cameras or other detection equipment to identify the hotspots and locate the exact location of the fire within the container.

If possible, separate the container from others by shifting or removing adjacent containers to create a firebreak. This can be done using onboard cranes or other cargo handling equipment.

In some cases, it may be necessary to jettison the container overboard to prevent the fire from spreading to other containers or the ship's structure. This is typically a last resort option and should only be done under the guidance of the ship's captain or firefighting team.

It's important to note that handling a container fire on a container ship can be complex and dangerous. It requires the expertise of a trained and experienced firefighting team, and all actions should be taken with caution and in accordance with established safety protocols.

A fire onboard an oceangoing vessel is not a situation anyone would want to be in. However, shipping cars in containers can offer methods to mitigate some of the risk associated with ocean transport of electric vehicles. The risks can be mitigated to a certain extent or eliminated completely. In the paragraphs below we look at how Kar-Tainer's Cassette Systems can support in this endeavor.

Risk Mitigation with Kar-Tainer

Besides having systems in place for swift detection of any fire, there are ways to mitigate the risk of shipping electric vehicles further. An obvious one would be to remove the battery all together. However, shipping a car which is not self-propelled offers its own challenges. When it cannot be driven up or down a ramp; in and out of a yard, it is difficult to process through the conventional vehicle logistics facilities and protocols. A vehicle which cannot move on itself has to be towed, lifted, or through similar means, positioned from factory, to port, stowed on a ship, and unloaded from vessel before being moved to a yard or facility in country of import where the battery can be installed. This type of move would in other words be impossible to do through the traditional Car Carrier/Rail + RoRo combination to move cars from factory to end market.

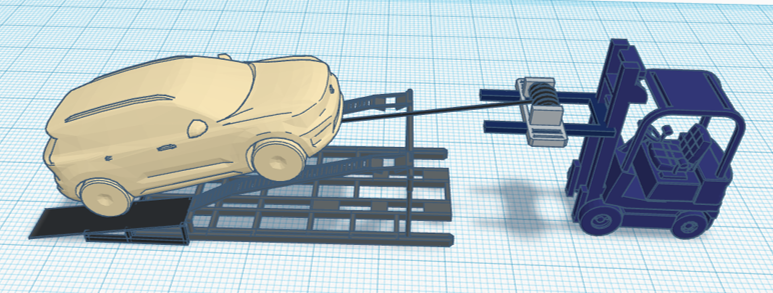

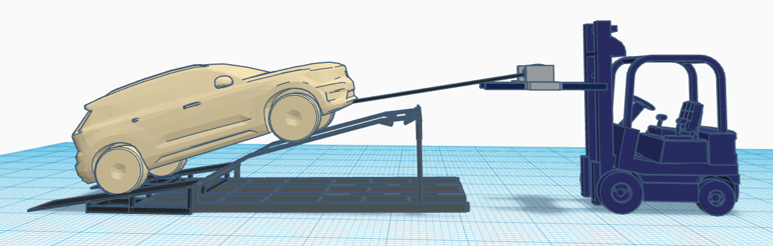

Kar-Tainers self-supporting CBU Cassette Systems on the other hand would be perfectly up for the task. Once a vehicle is loaded onto our cassettes the whole system with the car on top can freely be moved around with a forklift. We have contrived a device which allows us to load an EV without battery on to our standard cassettes without any hassle. As the vehicle cannot be driven onto the cassette, a pulley system attached to a forklift is used to pull the vehicle onto the cassette.

The vehicle would be positioned on the ground in front of the cassette, a driver would steer the car while the pulley system pulls it onto the cassette. This way a finished built car with only the battery missing would be able to move at ease all the way from the factory to a final assembly site in the country of import.

Another evident advantage of shipping cars in containers is negating the need for having any charge level at all on the battery. Most RoRo operators require a maximum charge level of 50%, but a minimum of 20% to safely be able to maneuver the car on and off the vessel and inside of vehicle yards. When shipping a car in containers using the Kar-Tainer Cassette system the cars could theoretically be shipped with a 0% charge level. This drastically reduces the chance of thermal runaway which is the main cause of fire outbreak from lithium-ion batteries.

If you want to learn more of the Kar-Tainer Cassette based Vehicle Transport systems and how these can help mitigate risk of shipping electric vehicles, get in touch with your closest Kar-Tainer representative or reach out to us through the website contact forms, on www.kar-tainer.com

Comments